Acoustics and Vibration Laboratory (CATMECH)

The Acoustics and Vibration laboratory of CATMECH has 300 m2 with equipment to carry out applied research in the field of acoustics and vibration. The infrastructure allows research to be carried out in order to advance the theoretical and experimental study of noise and vibration control.

Services it offers

- Active noise control. Theoretical study and optimization of the positioning of the necessary transducers in the control system. Application of active control systems in industrial machinery such as ventilation systems or transformers. Application of active control systems in openings. Realization of experimental measurements. Reduction of low-frequency noise in specific areas through the use of active application barriers in the field of construction.

- Environmental noise management. Prediction of noise and vibration induced by construction activities in nearby buildings. Experimental measurements. Environmental Acoustics: Sound characterization of urban and non-urban spaces. Sound characterization of exterior and interior spaces. Preparation of noise maps, capacity maps and action plans. Design and operation of low-cost acoustic sensor networks. Acoustic impact of leisure and transport infrastructures. Effects of noise on health.

- Location and characterization of sound sources of industrial and domestic machinery. Sound intensity measurements. aeroacoustics Application to the reduction of machinery noise.

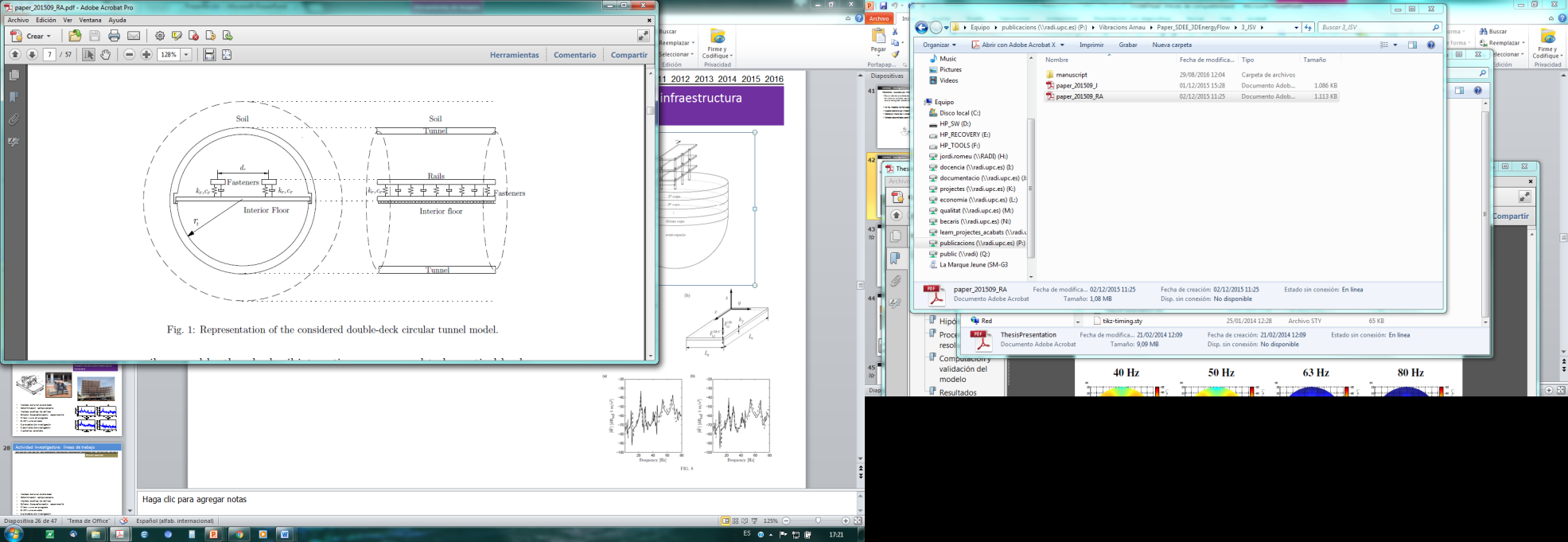

- Prediction and control of vibrations and noise induced by railway traffic. Forecast in the design phase of new railway lines. Prediction of buildings and singular cases by hybrid methods (experimental/numerical). Prediction of the effect of corrective solutions, such as blankets under ballast, floating slab track, low-stiffness fixings... Vibration measurements in tracks, tunnels, ground surface and buildings according to ISO 2631, ISO 10815 and ISO 14837. Dynamic characterization of lows and tracks and high-frequency components (ISO 10846, UNE 13481, UNE 13146, DIN 45673-5). Predictive models for interaction problems between pantograph and catenary. Specialty in rigid catenary. EN 50367 and EN 50318.

- Predictive maintenance procedure based on acoustic emission (very high frequency vibration). The detection of structural failures by acoustic emission has the advantage that it detects changes in the microscopic phase and allows maintenance tasks to be foreseen well in advance. This technique can be applied for the detection of a multitude of phenomena, such as leak detection, structural integrity, corrosion detection.

Innova Social Project

Challenge: use of sheep's wool as an acoustic absorbing material

Solution: design and experimental verification of acoustic absorption solutions based on sheep's wool.

Railtech project

Challenge: Dynamic in situ characterization of track fixing elements in railway infrastructure

Solution: Trial design and construction of own model on the infrastructure of the BCN metro L9.

Sener and Gamesa project

Challenge: Active noise control of wind turbine cooling equipment

Solution: A mock up is built in the laboratory where different configurations of active noise control are tested to reduce the general noise due to the ventilation of the refrigerator equipment, achieving a total cancellation of the frequency related to the passage of the Aleppo.

Equipment

- Data acquisition systems for noise and vibrations of different types

- Shaking tables

- Anechoic chamber

- Railway superstructure testbed

- Railway superstructure excitation systems

Share: