Advanced Center of Mechanical Technologies (CATMECH)

The Fluids laboratory of CATMECH has 500 m2 with equipment to carry out applied research in the field of fluids, oleo-hydraulics and pneumatics. CATMech's Fluids Division facilities offer technology advisory services and support for companies and academia from pre-design to numerical simulation and experimental testing.

Services it offers

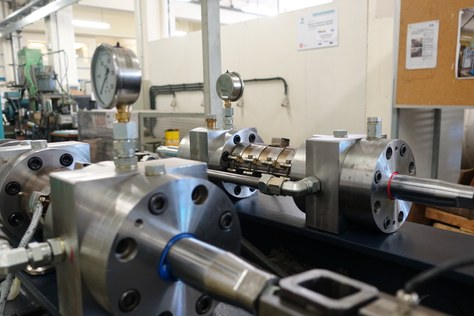

- The design, modeling and experimental characterization of fluid-dynamic, oleo-hydraulic and pneumatic components (pumps, valves, injectors, linear and rotary actuators, etc.) to study its efficiency, energy loss, instability and cavitation, static and dynamic resistance, level of noise and life cycle.

- Advance towards green and circular engineering through the optimization of hydraulic power transmission components and systems (for industrial and mobile "off-road" machinery) to study its functionality and connectivity, energy consumption, compatibility environmental, noise emissions and recyclability.

- The design and technological development of mini-micro-nano fluid components (for dosing, mixing, dispersion...etc.). For applications related to biotechnology and others.

- Training and awareness-raising activities between the university and the industrial and business fabric, in both directions: from the university to the company (beneficiary: the technical staff) and from the company to the university (beneficiary: the engineering student and researcher). The transfer of knowledge from the research center to the industry: teaching innovation to the future work in engineering.

Siemens-Gamesa project

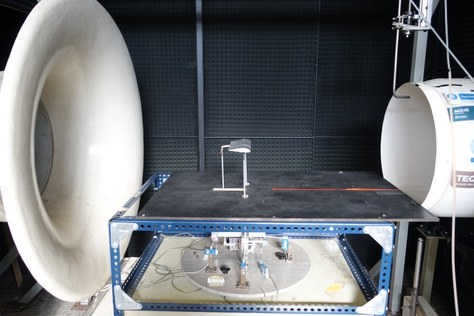

Challenge: Experimental validation of wind turbine nacelle cooling system

Solution: Design, manufacture and experimental test of a cooling system in the wind tunnel. The company's numerical model was validated by measuring the temperature map with various environmental conditions.

Project "Reagents for diagnosis"

Challenge: Compact system design for mass seeding of reagents and crops

Solution: Design, manufacture and testing of low-cost automated system for mass sowing of gelling agent and nutrient for mass cultivation.

Equipment

- Wind tunnel

- Physical variable measurement chains (mechanical / fluid-dynamic).

- Data acquisition and processing systems.

- Oil-hydraulic and pneumatic pressure groups up to 130 kW of installed power.

- Test benches for oleo-hydraulic components (pumps, valves, motors and cylinders).

- Test bench for mobile and agricultural machinery (mini backhoes, shovels, agricultural tractors, etc.).

Share: